This week there was a mix of things on the go, I cut another iteration for my organically shaped wooden bowl series, I did quite a bit of sanding and oiling of parts I'd already cut (then finally I spent Thursday cutting Quatrefoils for the Gothic Kitchen project.

The first two pictures below show a bit of a disaster I had on Monday while gluing the top of the bowl I made last week to its base. This was one of those situations I could see happening as I was doing it but still did nothing about until it was too late... you live and learn... or maybe you don't. Its been glued back together as well as I could with something so hard to clamp. I'll now oil it and still gold leaf the edge and maybe also gold leaf to highlight the repair as is the Japanese custom when fixing things. We'll see how it looks when done. At worst another useful experiment.

The last picture on the top row and the next three show a new bowl that I made which follows on from the one I cut last week. This incorporates distinct "legs" that blend into the organic surface. I really like how this has turned out and feel I'll make a lot of variations on this theme to create a collection that I can start to show to galleries or offer online. These look and feel amazing and I think once its oiled the grain and curvature will really show well. The part-sanded finish that leaves some machining marks in the part just adds to the texture and feel.

The first picture on the last row is an extra project I've been playing with this week. When our client for the Gothic Kitchen came into the workshop a couple of weeks ago I cut a walnut poppy to demonstrate the CNC cutting. I thought I would the result of this and make an ash plaque that this could be inlayed into. Then I thought it might also be good to have a go at hand-undercutting this so put a good few hours in with the chisels and dremel to cut behind the petals and add a texture to the surface. I was pleased with the result although it is time consuming - this shows it before finish.

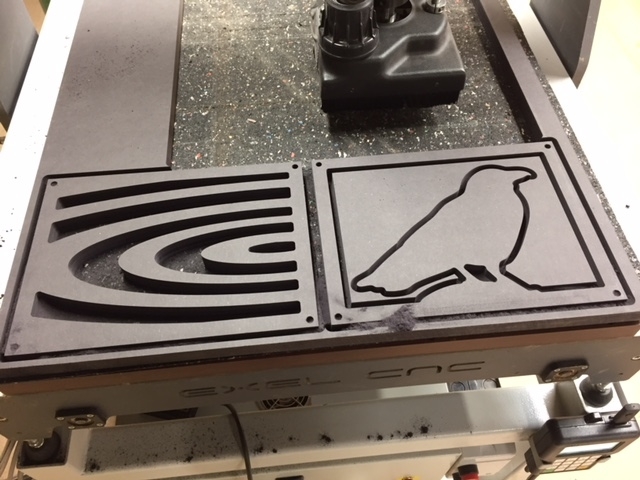

The last two image shows the rows of oak Quatrefoils that will run along the top of most of the cabinets in the Gothic Kitchen. Most of them I was able to cut in a single setup but the slightly longer one is shown on the CNC indexed to cut the full length. Each part took four tool changes to cut but they look great - particularly with the convex shape on the inside. For fun I shot a quick stop-motion video of a length being cut, you can watch the low-res video here.

Next week I expect to be making a lot more Gothic Kitchen parts... and thinking about how to start selling a few of the more product-type things I've been making.